STRUCTURAL DESIGN

Structural design for skid frames is an important aspect in the oil and gas, petrochemical, and process industries. Skid frames are typically used to support and integrate multiple pieces of equipment, piping, and instrumentation into a modular unit, facilitating transportation, installation, and maintenance. Technitas Pvt. Ltd. ensure that the structural design of skid frames involve seamless collaboration between structural engineers, equipment vendors, piping designers, and other disciplines to ensure a safe, robust, and practical design that meets the project requirements and facilitates efficient transportation, installation, and operation.

At Technitas Pvt. Ltd. we consider all the key steps involved in structural design for skid frames including:

➣ Design Codes and Standards: The structural design of skid frames is typically governed by relevant design codes and standards, such as ASCE/SEI 7-10 (Minimum Design Loads for Buildings and Other Structures), AWS D1.1 (Structural Welding Code - Steel), and local building codes or project-specific requirements.

➣ Load Identification and Calculation: Identify and calculate the various loads that the skid frame will be subjected to, including the weight of equipment, piping, and other components, as well as operational loads (e.g., wind, seismic, thermal expansion, and process loads). Consider both static and dynamic loads, as well as transportation and lifting loads during the handling and installation phases.

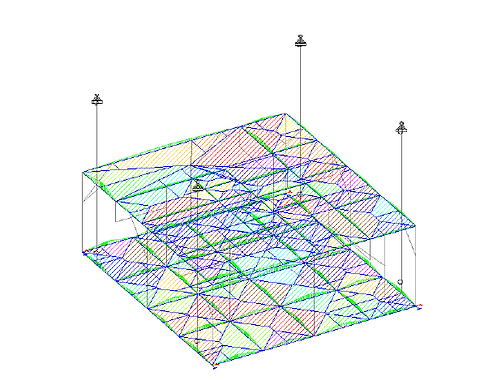

➣ Structural Modelling and Analysis: Apply the calculated loads to the structural model and perform static and dynamic analyses to determine stresses, deformations, and support reactions. Analyse the skid frame for different loading scenarios, including transportation, installation, and operational conditions.

➣ Member Sizing and Design: Based on the analysis results, we size the structural members (beams, columns, bracing, and base frames) to meet the design code requirements for strength, deflection, and stability. We optimize the member sizes to balance strength, weight, and cost considerations. Later, we design appropriate connections (welded or bolted) between structural members, ensuring adequate load transfer and compliance with design codes.

➣ Support and Anchorage Design: We design the support system for the skid frame, considering the weight distribution, anchor bolt locations, and foundation requirements. Calculate the required anchor bolt sizes, embedment depths, and spacing based on the applied loads and foundation conditions. We coordinate with civil/structural engineers for foundation design and anchoring details. All civil scope is typically excluded at our end.

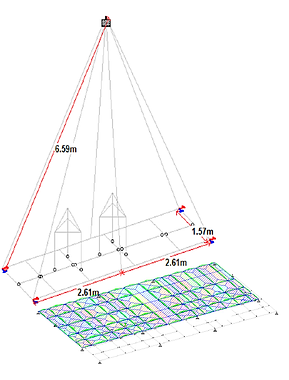

➣ Lifting and Transportation Design: After obtaining the COG, we eventually design the lifting lugs, spreader beams, or other lifting arrangements to facilitate safe transportation and installation of the skid frame. Perform lifting analyses to determine the appropriate lifting points, sling configurations, and lifting equipment requirements. Consider transportation constraints, such as clearances, weight limitations, and tie-down requirements, during the design process.

➣ Structural Detailing and Drawings: We prepare detailed fabrication drawings, including structural member dimensions, connection details, anchor bolt layouts, and any special instructions or requirements. Incorporate vendor information, equipment mounting details, and interface points into the structural drawings.

Review and Approval: We ensure that we reduce the client review cycle time to obtain necessary approvals from relevant authorities or certifying bodies.