EQUIPMENT DESIGN

At Technitas Pvt. Ltd., Static Equipment design involves thorough engineering calculations, adherence to relevant codes and standards, project specification, and considerations for various loading conditions, operational requirements, and safety factors.

Our software tools and team of checkers and reviewers ensure reduced client approval cycle time. We ensure that there is a seamless collaboration and effective interface between our designers and drafting team while performing mechanical design calculations, preparing drawings, and documentation.

In some cases, Finite Element Analysis (FEA) and other advanced computational methods are often employed for complex geometries or loading scenarios especially for nozzles which must sustain higher loading conditions, or in cases where fatigue analysis is required.

Equipment categories include the following: -

➣ Vertical pressure vessels are cylindrical vessels with their axis oriented vertically, commonly used for storage, processing, or separation of liquids and gases under pressure. Design aspects include shell thickness calculations, head types (e.g., ellipsoidal, hemispherical), nozzle reinforcements, and support types (skirt, leg, or trunnion).

This includes, Agitator vessels, tanks, reactors, filters, etc.

➣ Skirt Support

➣ Leg Support

➣ Trunnion Support

➣ Conical Bottom Head

➣ Horizontal Pressure Vessels - Horizontal pressure vessels are cylindrical vessels with their axis oriented horizontally, often used for storage or processing of liquids and gases. Design aspects include shell thickness calculations, head types (e.g., ellipsoidal, torispherical), saddle support locations, and nozzle reinforcements.

➣ Vessels with Limpet Coils / half-pipe jacket - Vessels with limpet coils have external coils or jackets attached to the vessel shell for heating or cooling purposes. Design considerations include coil sizing, coil attachment methods, thermal expansion provisions, and potential for shell temperature gradients.

➣ Jacketed Vessels – Consist of an outer jacket or shell surrounding the main vessel, creating an annular space that can be used for heating, cooling, or insulation purposes. Design aspects include jacket sizing, support arrangements, nozzle extensions, and provisions for thermal expansion.

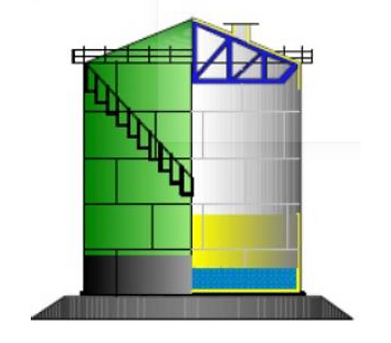

➣ Storage Tanks (API 650) - Large-scale storage tanks for liquids and gases are designed according to the API 650 standard, Key design factors include tank capacity, product density, operating pressure and temperature, roof type (fixed or floating), and foundation design.

➣ Rectangular tanks used for storage or processing of liquids and are designed based on principles from Roark's Formulas for Stress and Strain or Young's Formulas for Stress and Strain. Design considerations include plate thickness calculations, stiffener sizing and spacing, nozzle reinforcements, and foundation design.

➣ Heat Exchanger (TEMA) - Heat exchangers are designed to facilitate heat transfer between two or more fluid streams, following the standards set by the Tubular Exchanger Manufacturers Association (TEMA). Design aspects include shell and tube sizing, tube bundle layout, baffle spacing, and considerations for pressure drop, fouling, and thermal expansion.

➣ Columns/Tall Towers/Steel Stacks - Columns, tall towers, and steel stacks are vertical structures used for separation, absorption, or emission of gases or liquids. Design factors include column/tower height, diameter, wall thickness calculations, wind and seismic load considerations, and support structures (e.g., skirts, lugs, or guy wires).