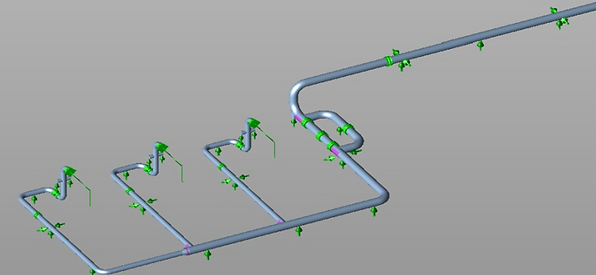

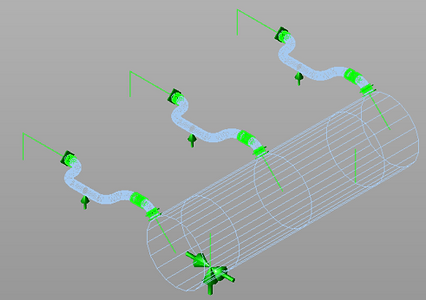

PIPE STRESS ANALYSIS

Pipe stress analysis is a critical aspect of piping design, ensuring that the piping systems can withstand various loads and stresses without failure or excessive deformation.

At Technitas Pvt. Ltd. we understand the importance of EPC client report formats and project specified loading combinations which form the basis of our analysis to consider factors such as thermal expansion, weight loads, pressure loads, wind and seismic loads, and other imposed loads. Upon completing the stress analysis, a comprehensive report is generated, we ensure that the pipe stress analysis process involves close collaboration between piping stress engineers, piping designers, and other disciplines to ensure that the piping systems are designed to withstand all anticipated loads and stresses while adhering to applicable codes, standards, and project specifications.

➣ Process Piping – Pipe stress analysis of these lines can be designed as per specified codes and standards such as ASME B31.3 – PROCESS PIPING

➣ Metallic or Non-Metallic Process Piping- The type of piping material, whether metallic (e.g., carbon steel, stainless steel, alloys) or non-metallic (e.g., plastic, fiberglass-reinforced plastic, rubber), plays a crucial role in the stress analysis. Different materials have varying properties, such as thermal expansion coefficients, allowable stresses, and temperature limits, which must be considered.

➣ Cladded or Non-Cladded Process Piping - Cladding is a process where a corrosion-resistant material (e.g., stainless steel) is metallurgically bonded to a base material (e.g., carbon steel). Cladded piping requires special considerations in stress analysis due to the different material properties of the cladding and the base material.

➣ Vacuum jacketed piping is a specialized piping system used in applications where highly efficient insulation is required, such as in cryogenic processes, liquefied gas handling, or low-temperature applications

➣ Pipelines - For long-distance pipelines, the stress analysis must account for factors like terrain profile, soil conditions, temperature variations, and potential ground movements or settlements. Specific codes and standards, such as ASME B31.4 and B31.8, are used for pipeline stress analysis.

➣ Slurry Piping - Pipe stress analysis of these lines can be designed as per specified codes and standards such as ASME B31.11 – Slurry Transportation Piping Systems.